Major Manufacturer of high quality tongue & groove wall paneling and edge glue laminated panels.

2 DAY ONLINE AUCTION

Greenwood Forest Products (1983) Ltd.

May 19TH & 20TH, 2021

Auction Starts Closing 10am both day.

PREVIEW- TUESDAY, May 18th, 9am to 4pm OR by prior appointment

PREVIEW LOCATION- 143 Green Mountain Rd, Penticton, BC

FOR MORE INFO CONTACT: Matt Ardiel @ mtardiel@tradewestsales.com

DAY 1 CATALOG & REGISTRATION

DAY 2 CATALOG & REGISTRATION

EQUIPMENT LISTING

TRIM LINE

- 4 STRAND PACKAGE BREAKDOWN DECK, 15' X 24'

- 3 ARM TILT HOIST, 15'W

- 4 STRAND LANDING TABLE, 15' X 12'

- 6 STRAND LUGGED TRIM TABLE, END & MIDDLE TRIM; 15'W X 8'

- 6 ROLL SPIRAL ROLLCASE, 15' X 16"

- ROLLCASE W/ (3) PNEUMATIC BOARD PUSHERS, END STOPS

- 3 STRAND SORT CHAIN, 7' X 36'; W/ (2) 2 STRAND TRANSFERS, 12' X 2'

- STICK TROLLEY

- INCLINE STICK BELT, 12" X 27'L; W/ GEAR DRIVE

- FLYTED WASTE CHAIN CONVEYOR, 10" X 20' BELOW TRIMMER, W/ MOTOR & REDUCER

RESAW LINE

- 4 STRAND INFEED PACKAGE BREAKDOWN DECK, 13' X 24'L; TO 4 ARM HYDRAULIC TILT HOIST

- WAYCON 5 STRAND TRIM TABLE, 13' TO 24'; (2) OVERHEAD ADJUSTABLE TRIM SAWS

- (2) CONTROL PANELS

- SWITCHES & FOOT PEDALS

- BELT CONVEYOR, 11" X 30'L; W/ DRIVE

- STENNER 42" VERTICAL RESAW, MODEL VHJ-105; S/N 842; W/ FEEDWORKS;

- INCLINE BELT CONVEYOR, 11" X 15'L; W/ MOTOR & REDUCER

- INCLINE CHEVRON BELT, 11" X 15'L; W/ MOTOR & REDUCER

- INCLINE BELT CONVEYOR, 11" X 16'; W/ MOTOR & REDUCER

- OUTFEED ROLLCASE, W/ PNEUMATIC BOARD PUSHERS, 3 STRAND OUTFEED TRANSFER

- STENNER 42” VERTICAL RESAW, MODEL VHE105; S/N 690; W/ FEEDWORKS; 40HP 230/460V;

- ADVANCE 7' SCISSOR LIFT, 6,000LB

- INFEED BELT CONVEYOR, 10'L

- RESAW OUTFEED BELT CONVEYOR, 12" X 7'L; 5HP DRIVE

MOULDER LINE

- SYSTEM TM INFEED ROLLCASE, 58" X 10'; W/ DRIVE; TO

- SCISSOR LIFT ROLLCASE, 58" X 10'

- SYSTEM TM/AS 3 STRAND LUGGED THROUGH TRANSFER, 7' X 30'

- OVERHEAD ADJUSTABLE 2 SAW TRIMMER; LASER GUIDES

- MOULDER BRIDGE W/ HOLD DOWN ROLLS

- (2) 7.5HP HYDRAULIC POWER UNITS (HYDRA)

- WASTE BELT W/ HOPPER

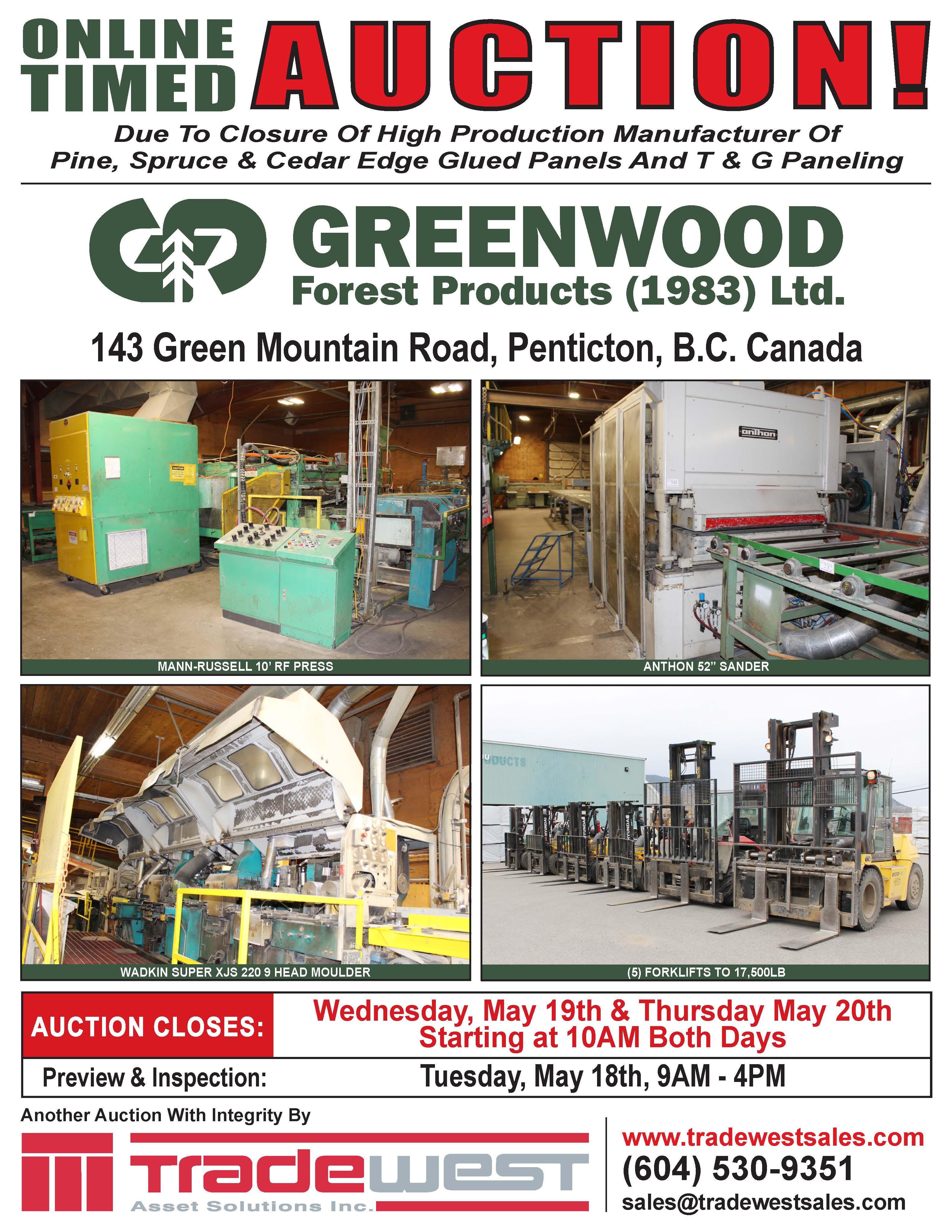

- WADKIN SUPER XJS220 9 HEAD HEAD MOULDER; 5” X 9” (130 X 230MM) CAPACITY; MIN SIZE FINISHED LUMBER: 15MM X 6MM THICK; 10 - 120M/MINUTE; JOINTED; 50MM SPINDLE;

- CONTROLS & TOOLING

- OUTFEED CONVEYOR BELT, 12" X 8'

- 4 STRAND PLASTIC CHAIN OUTFEED TRANSFER; 7' X 15'

- FOOT PEDALS

- (2) OUTFEED BELTS

- 40HP HYDRAULIC POWER UNIT, W/ (2) THERMAL TRANSFERS

2ND MOULDER RE-ENTRY

- SYSTEM TM 4 BELT DROP INCLINE

- SYSTEM TM DK-8300, 000

- 3 STRAND CHAIN TRANSFER, 6' X 3'

- 2003 WADKIN LAM 180 ULTRACARE 5 HEAD MOULDER; 130MM X 180MM CAPACITY; MIN. FINISHED SIZE: 80MM X 40MM THICK; MAX 120M/MIN.; 50MM SPINDLE; S/N 036212; 75HP; TIMBER LAMELLS, SIEMENS SIMATIC OP7 CONTROLS; SPLITTING HEAD, HEAD SEQUENCE: SAWING HEAD; 1ST BOTTOM HEAD; 1ST TOP HEAD; 2ND BOTTOM HEAD; 2ND TOP HEAD;

- SYSTEM TM 3 SECTION OUTFEED SYSTEM, BELTS, ROLLCASES, 5 BELT INCLINE TRANSFER

- 3 GRADER STATION OUTFEED SYSTEM FROM MOULDER

- BELT CONVEYOR, 10" X 30'L; W/ DRIVE

- WAYCON 5 STRAND BELT INCLINE TRANSFER, 6' X 18'

OPTIMIZED CHOP LINE

- ULTIMIZER 14B-100 SERIES II OPTIMIZING CHOP LINE, W/ INFEED & OUTFEED BELTS

- 6 STRAND UHMW LINE TRANSFER, 7' X 40'

- 2 SAW TRIMMER W/ LUGGED THROUGHFEED

- (9) LUMBER CARTS

- JOULLIN MATERIAL VACCUM LIFT, W/ OVERHEAD SYSTEM ON TRACKS; PIVOT TRANSFER, W/ HPU

- BELT CONVEYOR, 23" X 40'L

- 8 STRAND BELT SORT TRANSFER, 7' X 40'L

RF GLUE PANEL LINE, ANTHON SANDING & SIZING SYSTEM

- WAYCON 11 STRAND INCLINE BELT & PLASTIC CHAIN TRANSFER, 9’ X 45'L

- MANN-RUSSELL 10’ CONTINUOUS CROSS-FLOW LUMBER EDGE GLUER; RADIO FREQUENCY (RF) PRESS, 10' LINE, 480V, 103KVA; S/N S0061; ½” RO 1-1/2” STOCK THICKNESS; SPEED RANGE 2-12 FPM;

- AUTOMATED INFEED SECTION: USED FOR EDGE GLUING 20MM X 36MM LAMELS INTO A CHARGE UP TO 1220MMW AHEAD OF THE PRESS

- AUTO LOAD CONTROL TO 6.7 MhZ; SOLID STATE 3PH FULL WAVE BRIDGE RECTIFIER; SOLID STATE OVERLOAD PANEL; MANN-RUSSELL OSCILLATOR CIRCUIT, W/ TWIN VACUUM POWER TRIODES, OPERATING PUSH-PULL; INVOICE COST USD$439,000;

- MANN-RUSSELL 1750C RADIO FREQUENCY GENERATOR, W/ INFEED TRANSFORMERS;

- HIGH SPEED TRAVELING CUT-OFF SAW, 18” SAW BLADE 48 TOOTH STRAIGHT CARBIDE;

- (2) ALLEN-BRADLEY 1336 VARIABLE FREQUENCY DRIVES;

- DRY ICE MACHINE FOR RF PRESS CLEANING

- WAYCON RF PRESS DECLINE TRANSFER, 45" x 120’L;

- POWER U-SHAPED ROLLCASE INFEED TO SANDER;

- ANTHON 51" PANEL CALLIBRATION/SANDING MACHINE; MODEL CD6 WWS 130; S/N 99.2.-19; 6 HEAD; (4) 100HP MOTORS, (2) 50HP MOTORS; SANDING WIDTH: 1300MM; MIN/MAX HEIGHT: 155MM; FEED SPEED: 5-30M/MINUTE; WEIGHT 19.720 KG; INVOICED COST CAD $520,000; 480V

2002 ANTHON PANEL SIZER LINE:

ANTHON LNB/LNB-28.5/13.5 CNC PANEL SIZER FOR AUTO RIP & CROSS CUTTING OF SOLID WOOD; LENGTH 2800MM X WIDTH 1220MM; RAW BOARD MIN: 900 X 800MM; THICKNESS 12-38MM; RIPPING LENGTH: 2850MM; CROSS CUTTING LENGTH: 1350; MIN. FINISHED PART: 415 X 143MM; INVOICE COST CAD $1,391,000; COMPRISED OF:

- INSPECTION ROLLER TRACK W/ LIFTABLE FRAME

- OVERHEAD PUSHER SYSTEM

- BOOK FORMING STATION W/ LIFTING TABLE, MAX STACK 800MM

- ROLLER TRACK W/ FORKLIFT SLITS

- INTERMEDIATE POWER ROLLER TRACK

- ANGULAR SAW SYSTEM, INCLUDING:

- PREP TABLE FOR RIP CUT POSITIONING, GUIDE SYSTEM

- RIP SAW LNB 28.5: STRAIGHT RIP OR USED FOR TRIMMING APPROX. 20MM; SAW CARRIAGE SPEED 60M/MIN., & 80M/MIN RETURN;

- MACHINE PRESSURE BEAM ACTS AS SUCTION DUCT FOR SAW CLAMPS

- CROSS TRANSFER SYSTEM W/ LIFTABLE ROLLER TRACK FOR SMALL STRIPS

- PREP TABLE CROSS CUT SAW W/ POSITIONING FEEDER

- CROSS CUT SAW LNB 13.5

- SWITCHGEAR, MICRO PROCESSOR CONTROLS

- DESTACKING:

- INTERMEDIATE ROLLER TRACK W/ TRIM CUT SLUICE

- ANGULAR TRANSFER

ROBOT STACKER: YASKASWA MOTOMAN SP400X / XRC ROBOTIC PLACER; W/ REMOTE CONTROL; ATTACHED TO (4) CONVEYORS, PALLET STATION & PAPER ROLL STORAGE; HORIZONTAL STROKE 3100MM, VERTICAL STROKE 2200 MM; GRIPPER ARM CAPACITY 400KG; GRIPPING TOOLS IS FORK & PNEUMATICK HOLD-DOWN CYLINDERS

PACKAGING: SHRINK WRAP LINES & HEAT TUNNELS

- ADVANCE 5,000LB SCISSOR LIFT, 4’ X 8’;

- 9 RUN RUBBER BELT TRANSFER TABLE, 8’ X 12’L;

- POWER INFEED ROLLCASE, 30” X 10’L;

- POWER BRIDGE ROLLCASE, 27” X 10’L;

- RUBBER BELT INFEED CONVEYOR, 36” X 8’L;

- PACKAGING PARTS & SYSTEMS WRAPPING STATION; MODEL AL31WL; S/N E-60;

- PMI SHRINK WRAP TUNNEL, MODEL ST-901; S/N 02507;

- OUTFEED CONVEYOR;

ANTHON BOOK BUILDING & HANDLING LINE: PANELS 900MM TO 2435MM LENGTH BY 200MM TO 610MM WIDTH; (20) CYCLES PER MINUTE FOR 900MM LONG PANELS; W/ REMOTE CONTROLS; COMPRISED OF:

ACCELERATION SKEW CONVEYOR, 800MM WIDE X 5000MM

STACK BUILDING STATION;

CROSS BELT TRANSFER TO ANGULAR TRANSFER;

POWER ANGULAR TRANSFER;

(2) POWER ROLLER TRACKS, 2600 X 800MM

POWER ANGULAR TRANSFER UNIT, 2500 X 800MM

SIEMENS SWITCH CABINETS, CONTROL DESK & SIEMENS SIMATIC S7 MICRO-PROCESSOR CONTROL

ANTHON LABEL PLACING UNIT, MODEL LB-2, COMPRISED OF:

FRICTION FEEDER, MODEL LB-2; FEED WIDTH 250MM;

TRANSPORT CONVEYOR, 2500MM LENGTH; 800MM BELT WIDTH; 834MM CONVEYOR WIDTH; VARIABLE SPEED TO APPROX 35M/MIN;

DOUBLE SHEET CONTROL;

COVER FOR FRICTION FEED UNIT;

IONIZATION UNIT: CHARGIN ELECTRODE 30 KV; GENERATOR;

FORMAT SIZE: MAX 630 X 180MM; MIN 350 X 140MM;

LONGITUDINAL FEED; 35 CYCLES/MIN.;

SAMUEL SOA750-36 FULLY AUTOMATIC ORBITAL BANDER, S/N 750/36-10_ _ 051813; 110/240V 1PH

LABELLING SYSTEM;

POWER OUTFEED ROLLCASE, 30” X 6’L.

ISCO EL HIGH SPEED AUTO STACKER; MODEL EL96-2; S/N 00136; PLC & CONTROL;

RIGHT ANGLE INFEED TRANSFER: 30” X 9’L DROP ROLL ROLLCASE, W/ (7) 1” X 5’ RUBBER

CROSS FEED BELTS TO STACKER;

5’ X 8’ SCISSOR LIFT, POWER ROLLCASE TOP;

2 STRAND PACKAGE OUTFEED, 36” X 40’;

BATTERY POWERED STRAPPER.

ARPAC PACKAGE LINE #2

- 2002 ARPAC GREAT LAKES TS37 NE SHRINK WRAP SYSTEM, S/N 4815; CONTINUOUS MOTION ADJUSTABLE SIDE SEAL WRAPPER W/ SHANKLIN T-72 FREE STANDING HEAT TUNNEL; 5 RUN LATERAL INFEED TRANSFER, RUBBER RUNS ON WOOD FRAME; 12” X 17’ BELT INFEED CONVEYOR; BRAKED; (2) 12” X 10’ POWER ROLLCASES; AIR OP. PUSHOFF BAR TO DECLINE TIPPLE ROLL WITH BOTTOM STOP; 460V; INVOICE COST CAD $127,672;

- (2) SCISSOR LIFTS ON CASTORS

ARPAC PACKAGE LINE #3

- 4 RUN 12’ INFEED TRANSFER, RUBBER TUBE RUNS;

- POWER INFEED ROLLCASE, 12” X 9’

- 2008 ARPAC MODEL TS833CF SHRINK WRAP SYSTEM, S/N 10204; W/ WRAP DISPENSERS &

- RACKS;

- POWER OUTFEED ROLLCASE, 16” X 9’;

- 2008 ARPAC MPD1222120 12’ HEAT TUNNEL; S/N 11064

- POWER ROLLCASE, 12” X 10’; AIR OPERATED PUSH OFF BAR TO DECLINE 4 RUN TIPPLE ROLL

- TRANSFER W/ BOTTOM STOP;

STACKER LINE

- 3 STRAND DECK, W/ DRIVE

- 4 BIN SORTER SYSTEM, CHAIN DROP, 6' - 10'; TRACK SYSTEM

- 2 STRAND TRANSFER TO 2 ARM STUD STACKER, 4' ARM TO ARM

- ROLLCASE SCISSOR LIFT

- (4) ADVANCE SCISSOR LIFTS, 5,000LB

PACKAGING

- LM ELECTRIC PORTABLE PACKAGE SAW

- 9' HYDRAULIC PACKAGE SQUEEZE, 25HP HYDRAULIC POWER UNIT

- PACKAGE LINE SQUEEZE, INFEED TRANSFER, END BUMP, 2 STRAND OUTFEED TRANSFER

- HALTON SHRINK WRAPPER

- BANDING CART

- SIGNODE BATTERY POWERED STRAPPER

- SATO LABEL MACHINE

COMPRESSORS

- INGERSOLL-RAND 100HP SCREW COMPRESSOR, 145 PSIG; S/N IRN100H-CC; 56,509 HOURS; 460V

- GARDNER DENVER ELECTRA SCREW 100HP COMPRESSOR, 3,966 HOURS; 230/460V

- INGERSOLL-RAND AIR DRYER

- PURESTREAM AIR DRYER

- PALL E-844.51 TWIN COLUMN AIR DRYER

- EAGLE 7.5HP COMPRESSOR

- (3) AIR STORAGE TANKS

FILING

- WRIGHT W-150 HD B AUTO TOP & FACE CIRCLE SAW SHARPENER;

- WRIGHT W-350 SUPER HD DUAL SIDE GRINDER;

- ARMSTRONG 3-10-1 CIRCULAR SAW STRETCHER ROLLS;

- ARMSTRONG 2LH BANDSAW SHARPENER, W/ #58 CLAMP;

- ARMSTRONG 54-C MANUAL CARBIDE SAW POST GRINDER;

- GENERAL INTERNATIONAL 3 AXIS i-CARVER; MODEL 40-913M1; S/N 40568713;

- ASSORTED BLADES, ETC.

GRINDING

- WADKIN SILHOUETTE NNU PROFILE GRINDER; S/N 98-205; 9” (230MM) GRINDING WHEEL;

- 2004 WADKIN NZ300 PLANER HEAD GRINDER; 4” (100MM) GRINDING WHEEL; INVOICE COST CAD $31,175.00

- CUTTER HEADS

ELECTRICS

PDC ROOM "A"

- ELECTROTEK RSP HARMONIC REACTOR BANK, S/N 92-12238-2; 480V

- AUTO POWER FACTOR CORRECTION UNIT; 350KVAR @ 480V, 420KVAR @ 525V; MOD. R7230-250K5S5IOF480V; W/ ESTAMAT PFC12 DIGITAL CONTROL

- ELECTROTEK AUTO POWER FACTOR CORRECTION UNIT; SLAVE 300 KVAR @480V, 360 KVAR @ 525V

- FPE MAIN PDC, 1200 AMP; 277/480V

- FPE 2 SECTION MCC, 1200 AMP; 8 SWITCHES

- CUTLER-HAMMER TRU START BLOWER SOFT START

PDC ROOM "B"

- 1200 AMP MAIN, 347/600/1200 AMP

- (2) FPE 400 AMP, (6) 200 AMP, (2) 600 AMP, 30 AMP SWITCHES, ALL WITH RESETS

- ELECTROTEK AUTO POWER FACTOR CORRECTION UNIT, 400KVA @ 480V; 480KVAR @ 525V W/ ESTAMAT PFC12;

- WESTINGHOUSE 50KVA TRANSFORMER, 480-12/240V, 1PH

- WESTINGHOUSE 8 SECTION MCC, 40 SWITCHES

- 45KVA TRANSFORMER

- TECK CABLE ON SPOOLS

- EVI 50KVA TRANSFORMER, 480-120/240V

- SIEMENS SWITCHGEAR

- CUTLER HAMMER 800, 200, 30 AMP SWITCHES

- DELTA 37.5 KVA TRANFORMER, 480-120/240V

SHAVINGS & DUST COLLECTION

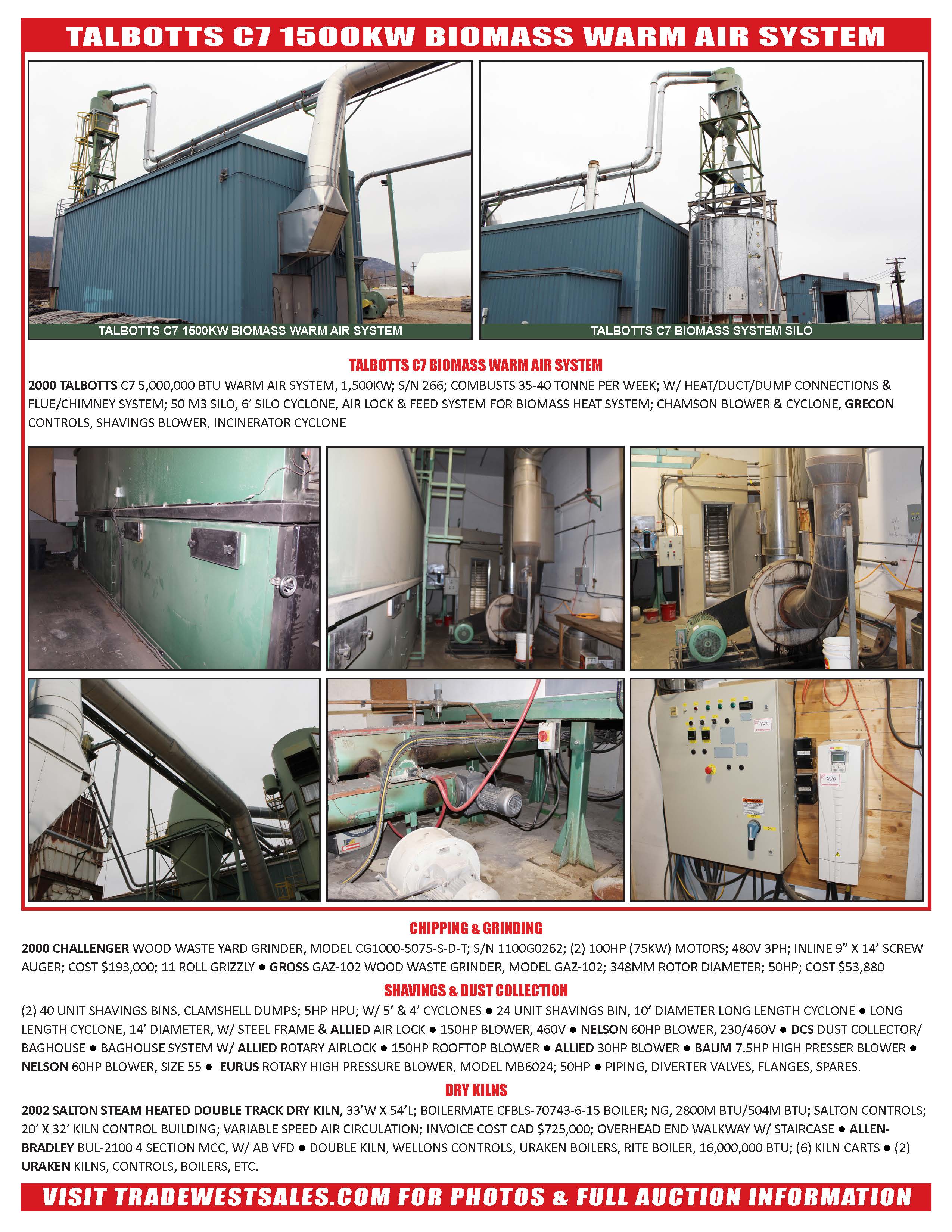

- 2000 TALBOTTS C7 5,000,000 BTU WARM AIR SYSTEM, 1,500KW; S/N 266; COMBUSTS 35-40 TONNE PER WEEK; W/ HEAT/DUCT/DUMP CONNECTIONS & FLUE/CHIMNEY SYSTEM; 50 M3 SILO, 6’ SILO CYCLONE, AIR LOCK & FEED SYSTEM FOR BIOMASS HEAT SYSTEM; CHAMSON BLOWER & CYCLONE, GRECON CONTROLS, SHAVINGS BLOWER, INCINERATOR CYCLONE

- (2) 40 UNIT SHAVINGS BINS, CLAMSHELL DUMPS; 5HP HPU; W/ 5' & 4' CYCLONES

- 24 UNIT SHAVINGS BIN, 10' DIAMETER LONG LENGTH CYCLONE

- LONG LENGTH CYCLONE, 14' DIAMETER, W/ STEEL FRAME & ALLIED AIR LOCK

- 150HP BLOWER, 460V;

- NELSON 60HP BLOWER, 230/460V

- DCS DUST COLLECTOR/BAGHOUSE

- BAGHOUSE SYSTEM W/ ALLIED ROTARY AIRLOCK

- 150HP ROOFTOP BLOWER

- ALLIED 30HP BLOWER

- BAUM 7.5HP HIGH PRESSER BLOWER

- NELSON 60HP BLOWER, SIZE 55

- EURUS ROTARY HIGH PRESSURE BLOWER, MODEL MB6024; 50HP

- PIPING, DIVERTER VALVES, FLANGES, SPARES.

CHIPPING & GRINDING

- 2000 CHALLENGER WOOD WASTE YARD GRINDER, MODEL CG1000-5075-S-D-T; S/N 1100G0262; (2) 100HP (75KW) MOTORS; 480V 3PH; INLINE 9” X 14’ SCREW AUGER; INVOICE COST $193,000; 11 ROLL GRIZZLY

- GROSS 50HP WOOD WASTE GRINDER, MODEL GAZ-102; 348MM ROTOR DIAMETER; 480V; INVOICE COST $53,880;

DRY KILNS

- DOUBLE KILN, WELLONS CONTROLS, URAKEN BOILERS, RITE BOILER, 16,000,000 BTU; (6) KILN CARTS

- (2) URAKEN KINS, CONTROLS, BOILERS, ETC.

- 2002 SALTON STEAM HEATED DOUBLE TRACK DRY KILN, 33'W X 54'L; BOILERMATE CFBLS-70743-6-15 BOILER; NG, 2800M BTU/504M BTU; SALTON CONTROLS; 20’ X 32’ KILN CONTROL BUILDING; VARIABLE SPEED AIR CIRCULATION; INVOICE COST CAD $725,000; OVERHEAD END WALKWAY W/ STAIRCASE

- ALLEN-BRADLEY BUL-2100 4 SECTION MCC, W/ AB VFD

MOBILE EQUIPMENT

- '18 MANITOU M-50-4 ALL WHEEL DRIVE ROUGH TERRAIN FORKLIFT; 11,000LB, ENCLOSED CAB; S/N 797760; 1,952 HOURS

- '15 HYUNDAI 80D-9 17,500LB FORKLIFT, ENCLOSED CAB; S/N HHKHFZ18LF0000019; 7,224 HOURS

- '16 HYUNDAI 33L-7M FORKLIFT, 6,500LB; LPG; PNEUMATIC TIRES; SIDE SHIFT; 3 STAGE MAST; S/N HHF21CG0000030 ; 3,529 HOURS; (UNIT #402)

- '12 HYUNDAI 30L-7M FORKLIFT, 5500LB, LPG, 3 STAGE MAST, SIDESHIFT, S/N HHF19PC000019

- '07 MITSUBISHI FG30-N-LP, 5500LB,

- LPG, PNEUMATIC TIRES, 3 STAGE MAST, SIDESHIFT, S/N AF11910349

GENERAL

- (10) SELF DUMPING WASTE HOPPERS

- CONCRETE DIVIDERS & LOCK BLOCKS

- CRIMPING MACHINE, TOOLS

- HOBART HANDLOV 13S

- WESTWARD FLOOR DRILL

- SPEEDON HORIZONTAL BANDSAW

- MILLER WELDER

- OXY-ACETYLENE RIG

- HAUSMANN TABLE SAW

- CHOP SAW, NAILER

- DELTA RADIAL ARM SAW

- CANARM 48” ROLLING FLOOR FAN

MAINTENANCE AREA, BOLTS, HOSE, OXY-ACET, FANS, WELDERS