TRADEWEST GLOBAL WEBCAST AUCTION!

WATER BOTTLING FACILITY

Gala Bay Springs Water Company

Vancouver, BC

Entire Near New Plant, Installed late 2019 just in time for COVID.

NEW Auction Closing Date: Friday, August 26TH, 2022

Preview : Thursday, August 25th 10AM-3PM OR By Prior Appointment (no drop in viewing)

Location: 8591 Fraser St, Vancouver, BC

Complete 5,000 bottle per hour bottle production and filling line for 350ml & 500ml bottles, consisting of blower moulder, unscrambler, filling machine, labeler and automatic conveying lines.

TO REGISTER TO BID CLICK HERE

* Auctioneer’s Note- Lots 101 to 108 are being offered as a complete line, and lot by lot. The winning bid(s) will be based upon the greater of the closing on Lot 100 (the "Entirety Bid"), or the aggregate sum of the individual "Lot" closing bids from 101 to 108 are being offered as a complete line, and lot by lot. The winning bid(s) will be based upon the greater of the closing on Lot 100 (the "Entirety Bid"), or the aggregate sum of the individual "Lot" closing bids from 101 to 108

SALE INCLUDES:

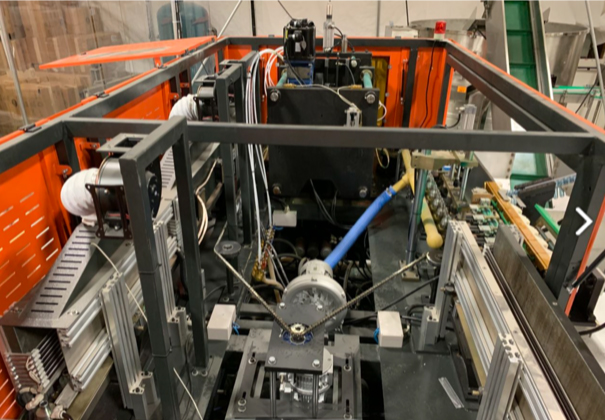

- 2018 Zhangjiagang Aqua Machinery Bottle Blow Moulding Machine; Model AM-4000; 6,000 Bottles/hour (BPH) Automatic 4 cavity 500ml bullet type bottle mould installed; w/ control panel, pre-form hopper, elevator conveyor, pre-form loader & (2) industrial chillers; Weight 3,900KG, Total system dimensions: 3,854 x 1,854 x 2417 mm;

- New Never Used 350 ml Bottle Mould;

- (3) 2018 Hengda High Pressure 20HP (15kW) Air Compressors, Model H1231D; for Blow Moulder;

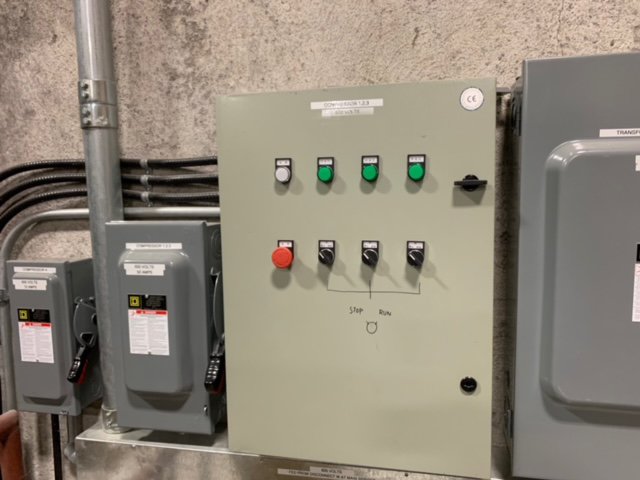

- High Pressure Compressor Control Panel; w/ sequential startup;

- 2018 Zhangjiagang Aqua Machinery Automatic Bottle Unscrambler, Model AM-12; Rated for 6,000 BPH Capacity, w/ bottle hopper (45-1/2” x 45-1/2” x 4’H) & incline feed conveyor (10’ x 13”) 104” high; 380V 50HZ 3 Phase; 1.5kW rated power; w/ HMI control;

- 2018 Zhangjiagang Aqua Machinery Bottle Air Conveyor, 4 Meters long;

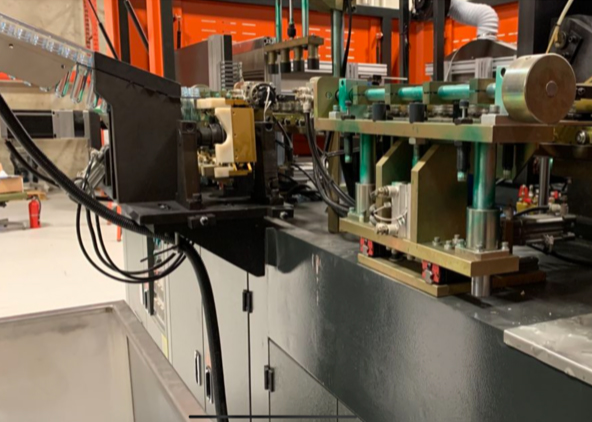

- 2018 Zhangjiagang Aqua Machinery Monoblock Filling Machine, Model CGF 14-12-5; 5,000 BPH; w/ 12 Position Rinser; 12 Head Filling Turret; 5 Head Capping Spindle, w/ cap hopper elevator, supply tank & centrifugal pump; 380V 50 HZ 3 Phase; w/ HMI VFD Controls (5) VFD’s; All infeed & outfeed conveyors are VFD controlled;

- 2019 VideoJet Laser Marking System, Including:

- 2019 VideoJet 3340 Laser Marking System; Model AL-76298; 9.3um, IP65;

- 2019 VideoJet 30W Marking Head, Model AL-78714; 30W marking head, SHC100D, w/

Beam expander, V=3.0 Black;

- 2019 VideoJet Laser Focusing module, F-200mm; Model AL-74989;

- 2019 VideoJet Blower Unit, Model AL-70629; AD350-A V/D; 115V (RoHS);

- 2019 VideoJet Model AL-78751; BTU 300mm SHC100/120D; VJA300,90;

- 2019 VideoJet AL-67620 Laser Interlock Switch;

- 2019 VideoJet Quick Connector Kit, Model AL-76476; Customer Interface I/O;

- 2019 VideoJet Language Kit, Model AL-76453; VJ3140/VJ3340; Canada.

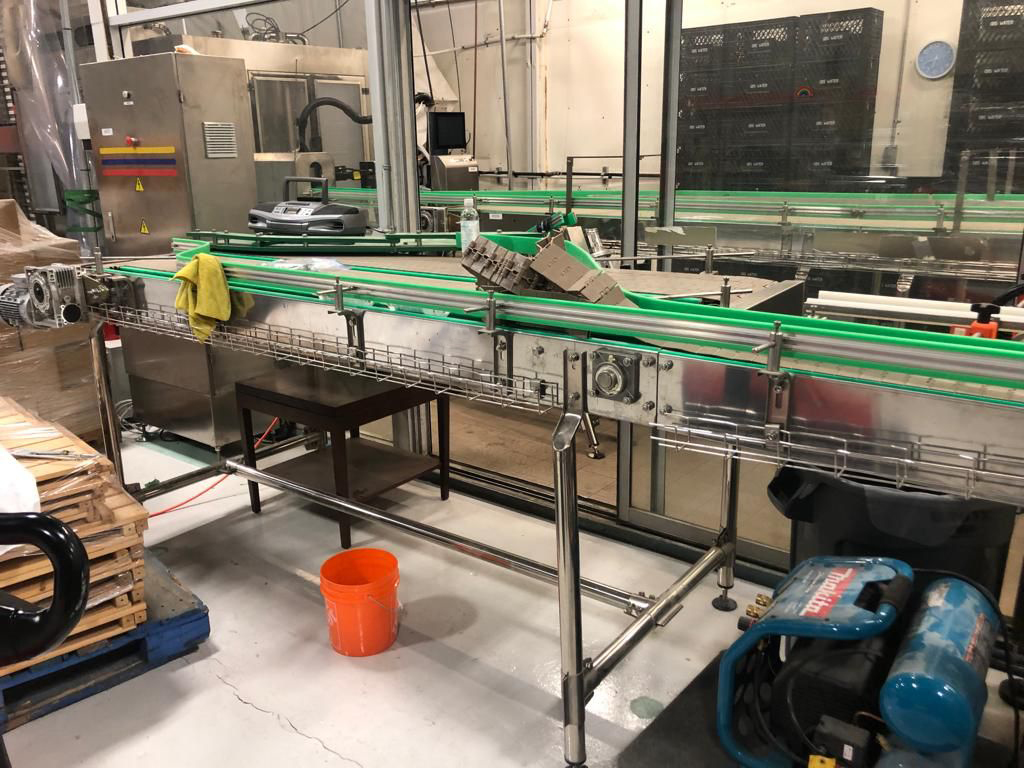

- Bottle Accumulating Diverter Table, 3-1/4’ belts x 13, 42-1/2”H; 16’ length, includes 7’ conveyor transfer into 3-in-1 machine; w/ Dyna-Par bottle counter;

- 2018 Zhangjiagang Aqua Machinery 90 degree bottle conveyor, 108”L x 30”W x 48”H (44” to belt top);

- 2020 Nita All Servo Labelling Machine; Model XP-100; s/n 1515-01-0819; AE616 STD; Metering belt, Orienting device, wrap station, overflow sensor; 200 – 240V 60HZ 1Ph.;

- 2018 Zhangjiagang Conveyor Buffer Table, w/ extension conveyor, 2,000 – 2,500 BPH;150”L x 49”W x 48”H (44” to belt top)

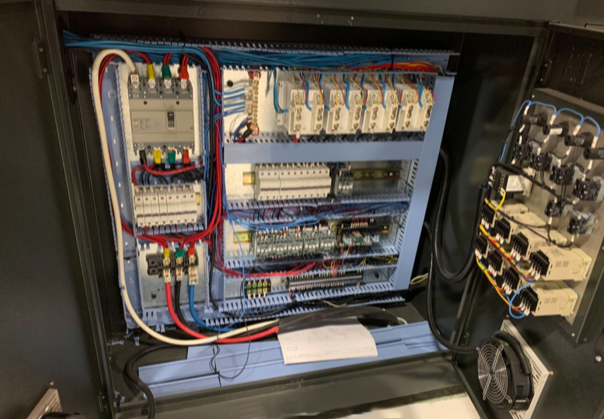

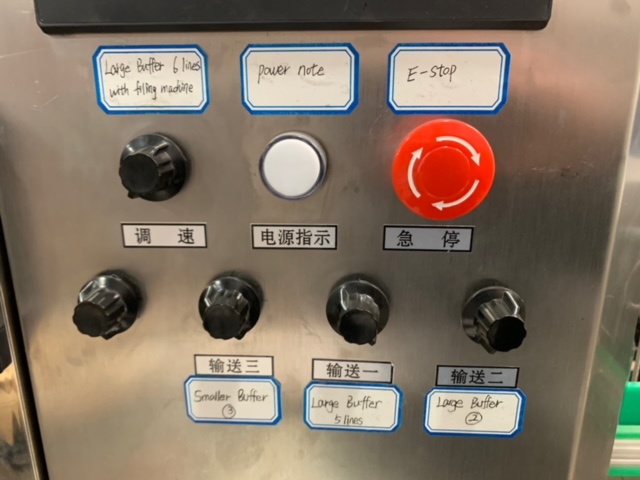

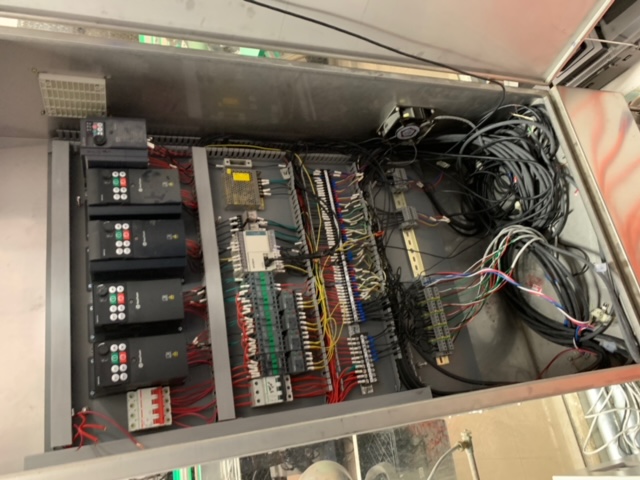

- 2018 Zhangjiagang Aqua Machinery Packaging Line control panel, incl. variable frequency drives;

- Water Intake System, 3,000 US Gallon Water Holding Tank; 2,500 US Gallon Water Holding Tank; pumps, valves, etc.;

- UV 1 & 2 Systems;

- 5 Micron Filters 1 & 2;

- 2018 Zhangjiagang Conveyor Buffer Table, 1,500 – 2,000 NPH Automatic Conveyor System, Total 23.5 meters long;

- 2018 Zhangjiagang Straight Conveyor, 1 Meter long;

- 2018 Zhangjiagang 90 Degree Conveyor, 1.1 Meter long;

- 2018 Zhangjiagang Labeller Infeed Conveyor, 1 Meter Long;

- 2018 Zhangjiagang Labeller Outfeed Conveyor, .7 Meter long;

- 2018 Zhangjiagang Transit Conveyor, 0.9 Meter x 2;

- 2018 Zhangjiagang Straight Conveyor, 2 Meters long;

- 2018 Zhangjiagang Straight Conveyor, 2 Meters long;

- 2018 Zhangjiagang 90 Degree Conveyor, 1.1 Meter long;

- 2018 Zhangjiagang Straight Conveyor, 2 Meters long;

- 2018 Zhangjiagang 3 in 1 Unit Outfeed Conveyor, 2.4 Meters long;

- 2018 Zhangjiagang Straight Conveyor, 2 Meters long;

- 2018 Zhangjiagang Air Conveyor Blower;

- High Pressure Compressor Air Pipe and Sensor;

- Water Pumps;

- Water Pump w/ Holding Tank;

- Carbon Filter;

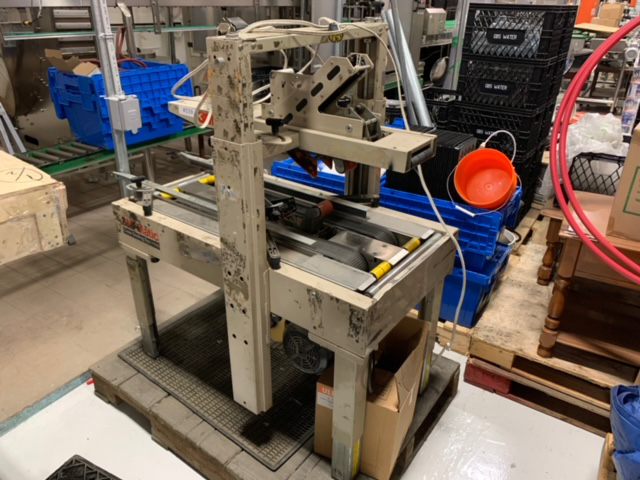

- Associate Label Custom Labeller, Panasonic Digital Readout

- Older 5 Gallon Filling Station; as is;

- Complete Reverse Osmosis Water Treatment System: TGI Topway Global Reverse Osmosis Sysetm; Steam Boiler; UV Water Treatment System;

- Baldor Reliance Electric Motor; 1.5HP;

Compressors & Air Dryers

- 2018 Hengda 7.5HP Low Pressure Air Compressor, Model 820;

- Ingersoll-Rand T30 10HP Compressor; 208/230/460V;

- Eagle 10HP Compressor, Model NOW-10-RB; 200V;

- Makita Air Compressor, Model MAC2400; 2.5HP 4.2 Gallon; 4.2 CFM 2 90 PSI;

- Husky Pro Air 2HP Vertical Portable Compressor, 135 Max PSI; 6.5scfm @ 40 psi;

- Ingersoll-Rand Dry Star Air Dryer; Model DS-10;

- Thomson-Gordon Air Dryer; Model TG-50;

- 2017 Hongfengda High Pressure Air Holding Tank;

ELECTRICAL

- 600V 150 Amp Power Infeed Safety Switch;

- Beaver 112.5 kVA Transformer, Model AVR112TQP4C /N, 600V – 380V; Type 2 Enclosure, 60HZ 3PH;

- 380V 150 Amp Safety Switch;

- Marcus 45kVA Transformer;

- 150 amp Switch;

BOXING & SHIPPING

- 3M Adjustable Case Taper-Sealer, Model 28600; 2’ x 1’ x 10’ Unilever conveyor

- 48” Rotary Scissor Lift Table;

- (25) Plastic Pallets;

- (40) Bottle Containment Shipping Rings;

- (2) Bay Warehouse Racking;

- (1) Bay Warehouse Racking;

INVENTORY

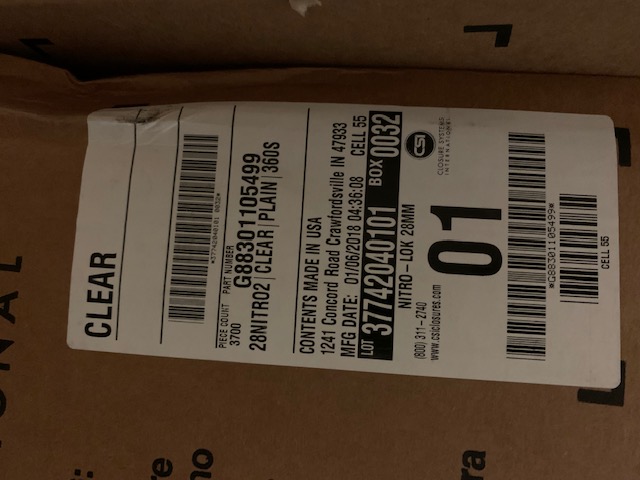

- Approx. 19.5 Large Boxes of Pre-formed 25 Gram Blue Plastic Slugs, 28mm bottle neck; (Approx. 122) Boxes of CSI Mfg. Velendo Bottle Caps, @ 2700 caps per box; 28mm bottle neck; Cost $7,000 in 2019;

- (10) IBC 1,000 Liter Plastic/Stainless Totes;

- Approx. 400 Black Plastic Stacking Bins.

BLOW MOULDER

WATER FILLING SYSTEM

VIDEOJET LASERMARKING SYSTEM

NITA LABELLING SYSTEM

AUTOMATIC BOTTLE UNSCRAMBLER

WATER FEED SYSTEM & TANKS

ELECTRICAL

COMPRESSORS

GENERAL

INVENTORY

PACKAGING & SHIPPING